3-D Scanning

Get to know our digital shipyard.

The advantages of applying 3-D scan technology are:

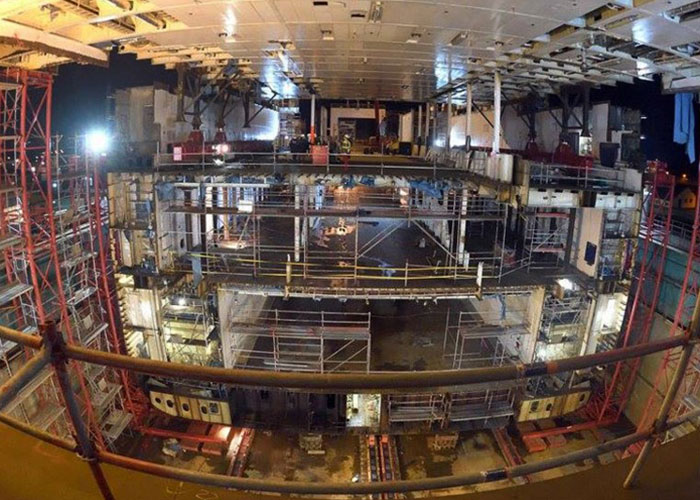

- capturing large and small structures in a detailed way

- precise measurements even under difficult conditions

- reduction of time, higher accuracy and completeness compared to manual measurements

This allows:

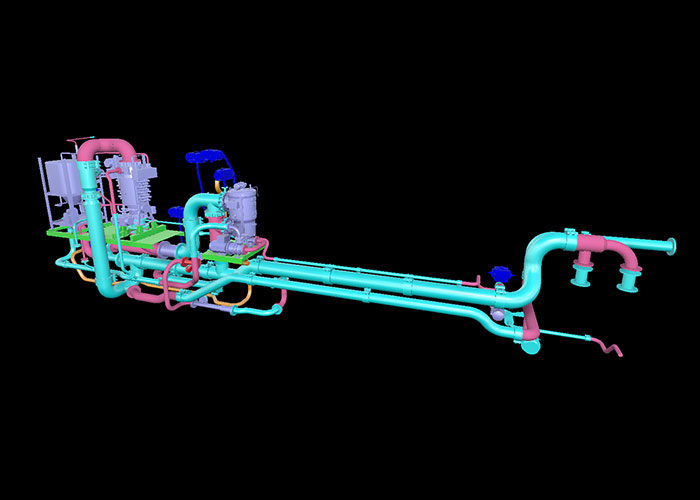

- pre-manufacturing to the maximum possible

- “turn-key” offers and supplies

- saving of time and costs

- customers a solid planning of time and budget

How does it work:

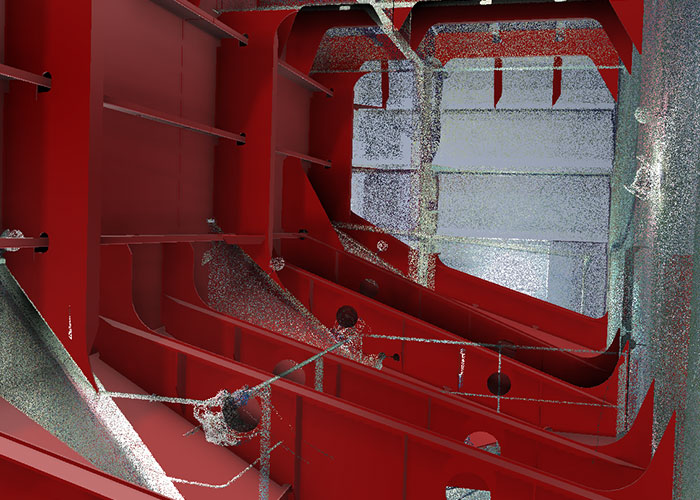

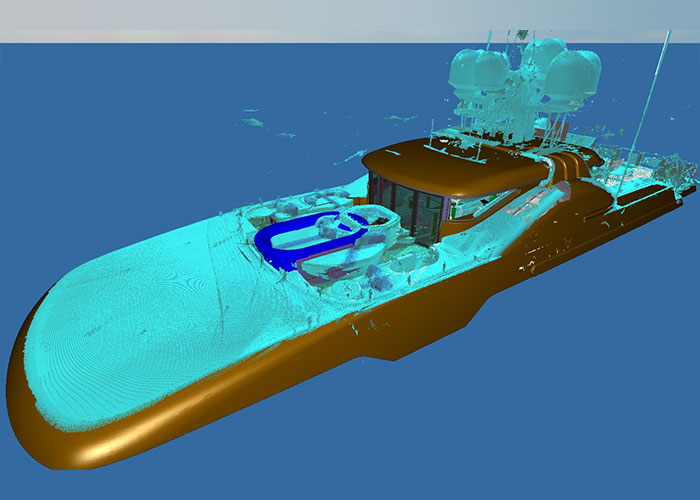

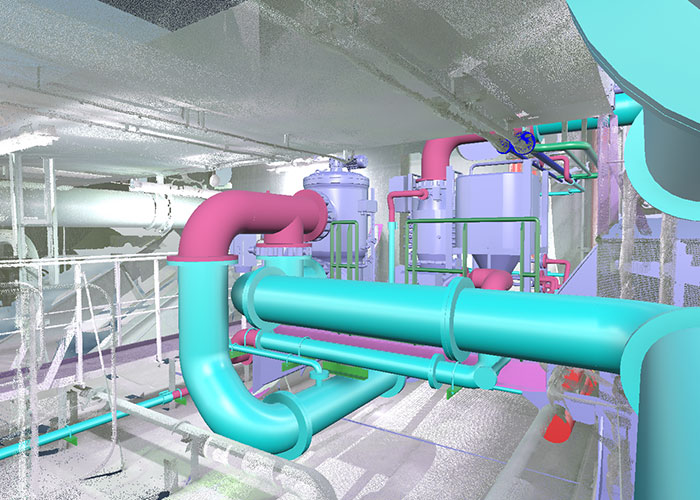

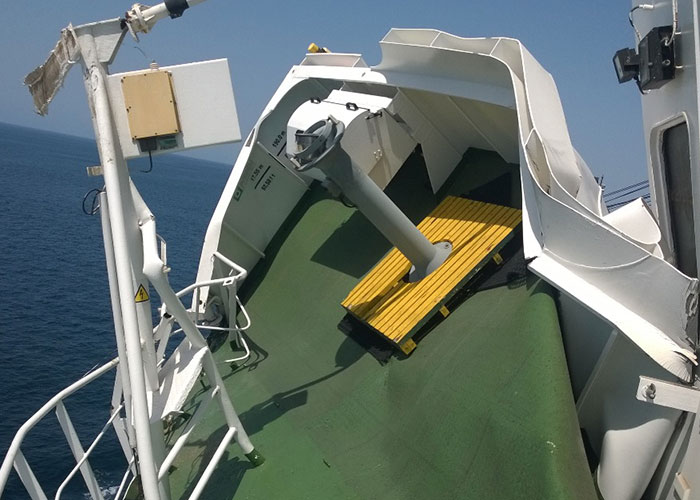

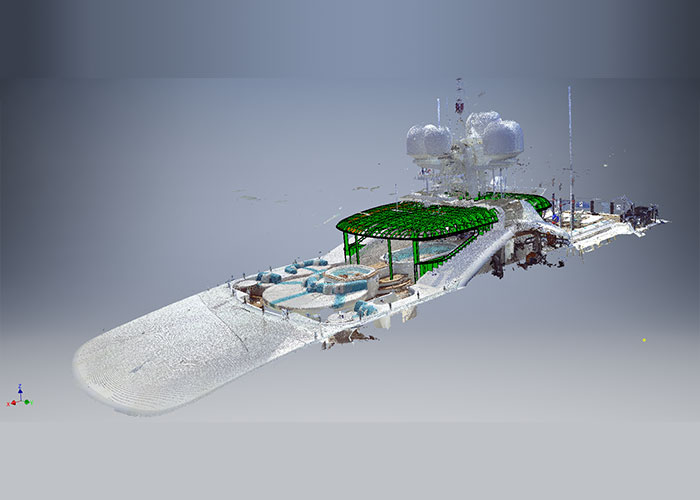

- A point cloud containing millions of single coordinates will be captured on board.

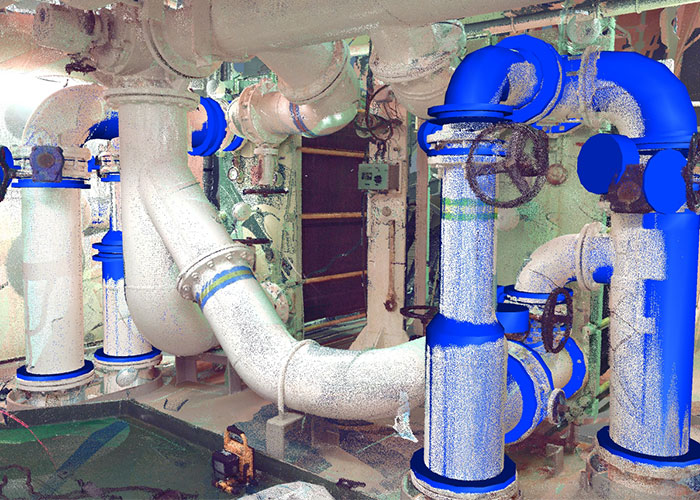

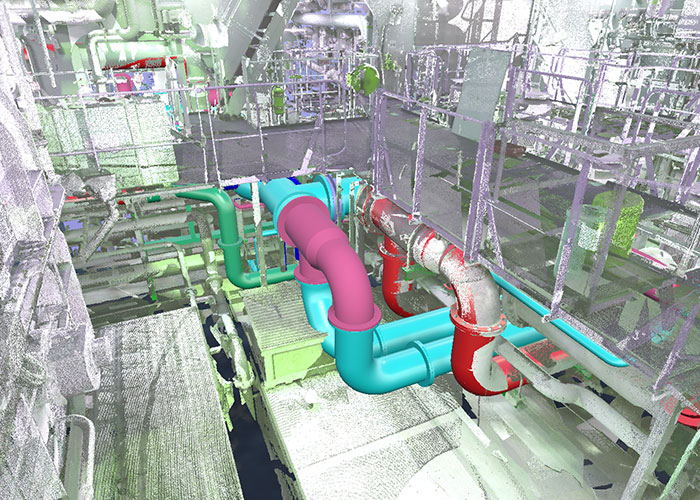

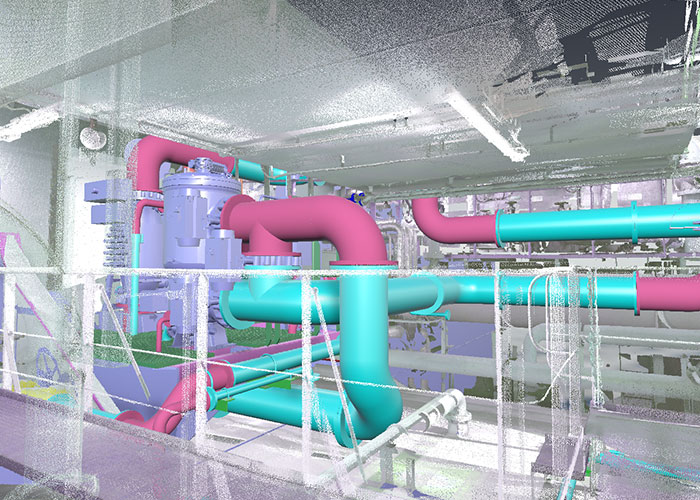

- The point cloud includes all equipment, pipes, cables and steel surroundings of the existing ship.

- We import this point cloud in our software as 3-D model environment in which we are able to measure and provide our engineering services.

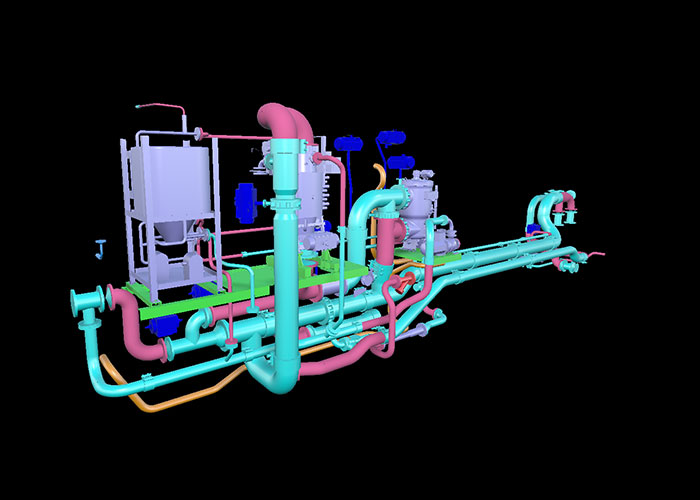

- We virtually place the new components into the existing environment and do the system engineering.

- We prepare a complete 3-D model of the retrofitted environment.

- We provide a 3-D model review in virtual reality for your perusal.

- We deliver the engineering package for the retrofit.

For more information please see our flyer or contact us for a presentation.